Have you ever bought something for a project, only to realize later that it wasn’t the right fit at all? It happens more often than you think—especially when people try to choose acrylic materials in a hurry. And here’s the funny part: even with many Acrylic Sheet Suppliers in Dubai available today, most shoppers repeat the same mistakes without even realizing it. So if you’re planning to buy acrylic products soon, you’re already ahead of the curve by learning what not to do.

Let’s walk through the most common slip-ups people make and how you can avoid them like a pro.

1. Not Checking the Acrylic Grade

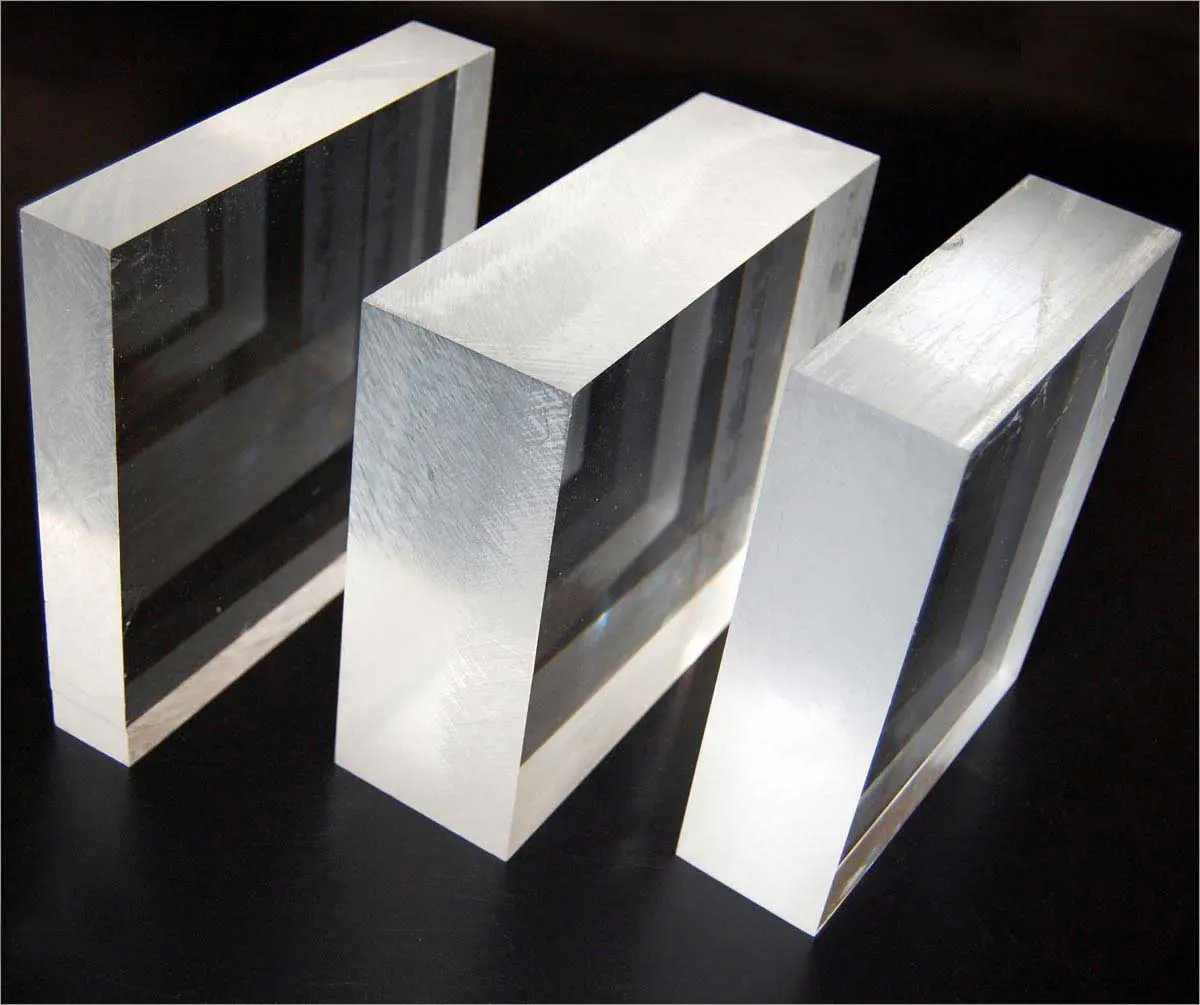

Acrylic isn’t one-size-fits-all. There’s cast acrylic, extruded acrylic, impact-modified acrylic… and each behaves differently. If you don’t match the grade to your project requirements, you may end up with cracking, yellowing, or warping later.

2. Assuming All Thicknesses Work the Same

A 2mm sheet might be perfect for signage but terrible for shelving. Thickness directly affects strength, clarity, and cost. Don’t eyeball it—know your load requirements.

3. Ignoring UV Protection Needs

Dubai’s sunlight doesn’t play around. A sheet without UV resistance can fade or develop hairline cracks quickly. Some customers skip this feature to save a few dirhams, but regret it later.

4. Not Asking About Temperature Tolerance

Acrylic has different melting and softening thresholds. If your piece will be exposed to heat—like outdoor displays or kitchen areas—temperature performance matters more than you think.

5. Forgetting About Edge Finishing

Sharp or rough edges can ruin the look of an otherwise great project. Make sure your supplier offers laser-cutting, polishing, or flame finishing if the edges will be visible.

6. Choosing Based on Price Alone

Cheap sounds good until your acrylic bends, scratches, or breaks. You don’t have to buy the most expensive sheet—just something that’s actually right for your application.

7. Not Clarifying the Type of Transparency

Fun fact: acrylic can be crystal-clear, frosted, tinted, opaque, or even textured. Many buyers assume “clear” is the only option and then feel disappointed when the wrong finish arrives.

8. Skipping the Sample Check

You wouldn’t buy a sofa without touching the fabric, right? Same concept here. Get a sample if you’re unsure. A small check now saves big trouble later.

9. Overlooking the Supplier’s Cutting Accuracy

Sometimes suppliers promise “custom cutting,” but the final product arrives with uneven edges or incorrect sizing. Always ask about tolerances and machinery type.

10. Forgetting About Protective Films

Acrylic sheets usually come with protective layers to avoid scratches during transport. Some people remove them too early or don’t make sure they’re included in the first place.

11. Not Checking for Warranty or Replacement Options

A good business stands by the quality of its acrylic. If a supplier avoids talking about warranty terms, that’s your cue to keep looking. You’ll see—these policies matter when issues come up.

12. Assuming All Colors Are Always in Stock

Acrylic comes in dozens of colors, but not all sheet businesses keep every shade on hand. If you need something specific, pre-check availability to avoid delays.

13. Misjudging the Installation Requirements

Some people buy thick or heavy sheets without considering whether it’ll be difficult to install. Acrylic is generally light, but large pieces can still be tricky to handle.

14. Not Asking About Custom Fabrication

Cutting isn’t the only service. Bending, laser engraving, thermoforming, and bonding are often needed too. Missing this step means you might have to look for multiple vendors unnecessarily.

Don't forget to check out: Step-by-Step Guide to Working With Cake Topper Suppliers Dubai for Large Events

15. Choosing a Supplier Without Checking Reviews or Past Work

This is one of the biggest red flags. Dubai has many sheet businesses, but not all focus on quality. Look at photos, customer experiences, and reputation. A little research goes a long way.

Why These Mistakes Happen

Most people simply assume acrylic is simple to purchase—like buying a plastic cover. But acrylic is a technical material with many variables. In addition, people rush their decisions, especially when dealing with tight project timelines.

If you slow down just a little and ask the right questions, you’ll avoid nearly all the issues above.

How to Avoid These Mistakes Altogether

Here’s the thing: the easiest way to avoid these problems is to partner with a supplier who actually educates you instead of rushing you to buy. A good business will ask you questions about your project and guide you toward the right material, thickness, and finish.

This is where knowing the right Acrylic Sheet Suppliers in Dubai truly makes your experience smoother.

Conclusion

Choosing acrylic products isn’t complicated once you understand the basics and steer clear of the common mistakes people make. From checking thickness to understanding UV protection, these small steps can save you money, effort, and frustration later on. And if you want reliable guidance and high-quality products, companies like Pleasant Plastic consistently help customers make informed decisions without the usual confusion. Take a little time, ask the right questions, and you’ll end up with exactly what your project deserves.

FAQs

1. Are acrylic sheets durable enough for outdoor use?

Yes—when UV-protected. Always confirm this feature for outdoor projects.

2. What’s the difference between cast and extruded acrylic?

Cast acrylic offers better clarity and strength, while extruded is more affordable and easier to cut.

3. Can acrylic sheets be laser cut?

Absolutely. Laser cutting gives smooth edges and precise shapes.

4. Do acrylic sheets scratch easily?

They’re more scratch-resistant than many plastics, but still require careful handling.

5. Is acrylic suitable for custom-shaped signage?

Yes! It’s one of the most popular materials for signage due to clarity, stability, and formability.

Write a comment ...